What is a BCI battery? If you’ve ever found yourself pondering this question, you’re in the right place. BCI, or Battery Council International, refers to a standard sizing system for automotive batteries. But it’s not just about size – BCI batteries are designed to power various vehicles, from cars and trucks to motorcycles and boats. In this article, we’ll delve deeper into what BCI batteries are, how they work, and why they are essential for keeping our vehicles running smoothly. So, let’s jump right in!

What is a BCI Battery?

A BCI battery, or Battery Council International battery, is a specific type of battery that follows the standards set by the Battery Council International. BCI is a trade association that represents the lead-based battery manufacturing industry in the United States. BCI batteries are commonly used in automotive applications and are designed to provide reliable power for starting and running vehicles.

Understanding BCI Battery Sizes

BCI batteries come in various sizes, and each size is designated by a specific code. The BCI battery size code consists of a combination of numbers and letters that indicate the battery’s dimensions, capacity, and terminal configuration. Here are some common BCI battery sizes:

Group 24

– Dimensions: 10.25″ x 6.8125″ x 8.8125″

– Capacity: Typically around 70 ampere-hours (Ah)

– Terminal Configuration: Top terminals

Group 35

– Dimensions: 9.0625″ x 6.875″ x 8.875″

– Capacity: Typically around 48 Ah

– Terminal Configuration: Top terminals

Group 48

– Dimensions: 10.875″ x 6.75″ x 7.875″

– Capacity: Typically around 70 Ah

– Terminal Configuration: Top terminals

These are just a few examples of BCI battery sizes. It’s important to check the specific size requirements for your vehicle before purchasing a BCI battery to ensure compatibility.

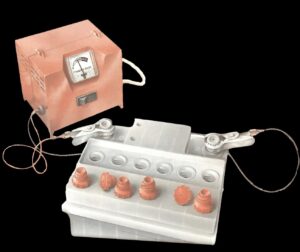

The Anatomy of a BCI Battery

To better understand what a BCI battery is, let’s take a closer look at its components and how it functions.

1. Battery Case

The battery case is the outer shell of the BCI battery, typically made of a durable and impact-resistant material like polypropylene. It provides protection for the internal components and helps contain any potential leaks or spills.

2. Electrolyte Solution

Inside the battery case, there is an electrolyte solution, usually a mixture of sulfuric acid and distilled water. The electrolyte serves as a conductor and facilitates the flow of electric current between the battery’s positive and negative terminals.

3. Positive and Negative Plates

A BCI battery consists of a series of positive and negative plates. These plates are made of lead or lead-alloy and are coated with a paste-like mixture of lead oxide and sulfuric acid called active material. The positive plates are typically coated with lead dioxide (PbO2), while the negative plates are coated with pure sponge lead (Pb).

4. Separator

The positive and negative plates are separated by a non-conductive material called a separator. The separator prevents direct contact between the plates, reducing the risk of short circuits while allowing the flow of electrolyte ions.

5. Terminals

The terminals on a BCI battery are the points of connection for electrical devices. They provide a means for the battery to deliver power and receive a charge. BCI batteries generally have top terminals, but some may also have side terminals or a combination of both.

6. Vent Caps

Vent caps are located on top of the battery and serve as a safety feature. They allow the release of gases that can accumulate during the battery charging process, preventing excessive pressure buildup.

Advantages of BCI Batteries

BCI batteries offer several advantages over other types of batteries. Here are some key benefits of using BCI batteries:

1. Reliable Starting Power

BCI batteries are specifically designed for automotive applications, providing the necessary starting power to ignite the engine and get your vehicle running smoothly. They have a high cranking power, allowing them to deliver a burst of energy to start the engine even in cold weather conditions.

2. Durability and Longevity

BCI batteries are built to withstand the demands of automotive use. They are designed to be durable and reliable, with the ability to handle the vibrations, temperature variations, and other harsh conditions experienced in a vehicle’s engine compartment. With proper maintenance, BCI batteries can have a long service life.

3. Wide Availability

BCI batteries are widely available and can be found in numerous automotive supply stores, making them easily accessible for replacement or upgrade purposes. Their standardized sizing also ensures compatibility with a wide range of vehicles.

4. Compatibility with Vehicle Electronics

Modern vehicles rely heavily on electrical systems for various functions, from entertainment systems to advanced safety features. BCI batteries are designed to provide the necessary power and voltage levels required by these systems, ensuring compatibility and optimal performance.

Maintaining and Replacing BCI Batteries

To maximize the lifespan and performance of your BCI battery, it’s important to follow proper maintenance practices and know when it’s time for a replacement. Here are some tips on maintaining and replacing BCI batteries:

1. Regular Inspection

Periodically inspect your BCI battery for any signs of damage, leakage, or corrosion. Check the terminals for tightness and cleanliness, ensuring a good connection. If you notice any issues, take the necessary steps to address them promptly.

2. Cleaning the Battery

Clean the battery terminals and connectors using a mixture of baking soda and water to remove any corrosion or buildup. Disconnect the battery cables before cleaning and ensure they are securely reconnected afterward.

3. Battery Charging

If your vehicle has been sitting idle for an extended period, consider using a battery charger to maintain the charge level of your BCI battery. This is especially important during colder months when batteries can discharge more quickly.

4. Testing and Replacement

When your BCI battery starts showing signs of deterioration, such as difficulty in starting the engine or frequent power failures, it may be time for a replacement. You can have the battery tested at an automotive service center to determine its health and capacity.

BCI batteries are an essential component of automotive systems, providing reliable starting power and electrical support for various vehicle functions. Understanding the basics of BCI batteries, including their sizes, anatomy, and advantages, can help you make informed decisions when it comes to maintenance and replacement. By following proper maintenance practices and seeking professional assistance when needed, you can ensure optimal performance and longevity for your BCI battery.

Frequently Asked Questions

What is a BCI battery?

A BCI (Battery Council International) battery is a type of automotive battery that is commonly used in vehicles such as cars, trucks, and motorcycles. It is designed to provide the electrical power needed to start the engine and to run various electrical components while the engine is not running.

How is a BCI battery different from other types of batteries?

A BCI battery is specifically designed for automotive applications and differs from other types of batteries, such as deep cycle or marine batteries, in terms of construction and performance characteristics. BCI batteries are designed to deliver short bursts of high current, which is essential for starting the engine, whereas deep cycle batteries are designed to provide a steady amount of power over a longer period of time.

What are the main components of a BCI battery?

A BCI battery consists of several key components, including lead plates, an electrolyte solution, a plastic case, terminals, and a vent cap. The lead plates are the active elements of the battery that produce and store electrical energy. The electrolyte solution facilitates the flow of ions between the plates, while the plastic case houses and protects the internal components. The terminals provide the connection points for electrical cables, and the vent cap allows for the release of gases that are produced during the battery charging and discharging processes.

How long does a BCI battery typically last?

The lifespan of a BCI battery can vary depending on several factors, including usage patterns, maintenance practices, and environmental conditions. On average, a well-maintained BCI battery can last anywhere from 3 to 5 years. However, it is important to note that certain conditions, such as extreme temperatures or frequent deep discharges, can significantly reduce the battery’s lifespan.

Can a BCI battery be recharged?

Yes, a BCI battery can be recharged using a battery charger or by running the engine of the vehicle. When the engine is running, the alternator generates electricity that is used to recharge the battery. It is important to ensure that the battery is properly connected to a charger or vehicle’s charging system to avoid any damage to the battery or electrical components.

Are BCI batteries recyclable?

Yes, BCI batteries are highly recyclable. They are made from materials such as lead, plastic, and sulfuric acid, which can be recycled and reused to manufacture new batteries. Recycling BCI batteries not only helps conserve resources but also prevents the release of harmful substances into the environment. It is important to dispose of old batteries at designated recycling centers or through authorized recycling programs.

Final Thoughts

A BCI battery, also known as a Battery Council International battery, is a type of battery commonly used in automotive applications. It follows specific standards set by the Battery Council International (BCI) to ensure compatibility with various vehicles. BCI batteries are designed to provide reliable power for starting engines and running electrical systems in cars, trucks, and other vehicles. They come in different sizes and configurations to fit specific vehicle requirements. Overall, a BCI battery is a crucial component in ensuring the efficient functioning of vehicles’ electrical systems and is an essential part of the automotive industry.